Alamathy Factory

(near Chennai)

The manufacture of Polymeric waterproofing membranes and anti-corrosive tapes requires complete facilities for handling and processing of bitumen. IWL in collaboration with European experts, set up a completely automated, digitally controlled and monitored facility at Alamathy (near Chennai), it’s first factory, for the above purposes. It was built in 1988 and commissioned in 1990. It is spread over 250,000 square feet of industrial land. It is in close proximity to sources of raw materials especially the oil refinery at Manali (Tamil Nadu) which is the major supplier of Bitumen. It is also near the Chennai Port to facilitate imports and exports.

Wada Factory

(near Mumbai)

Commissioned in 2010, the Wada factory, near Mumbai, is established in 100,000 square feet of Industrial Land. IWL input it's many years of experience in bitumen handling and processing while constructing the plant. The outcome is a modern, compact facility, with high output and significant finished product storage capacity to instantly cater to customer requirements. Sales from IWL's Wada plant now constitute a significant proportion of IWL's turnover.

Bobbili Factory

(near Visakhapatnam)

IWL's third manufacturing unit was commissioned at Bobbili, Andhra Pradesh in 2014. It is IWL's largest emulsion manufacturing facility and has the capacity to manufacture more than 150 MT of Emulsion per day. The Bobbili plant is now catering to our valued customers in Andhra Pradesh, Orissa and Chattisgarh. The product has been well received and the quality levels match IWL's usual high standards.

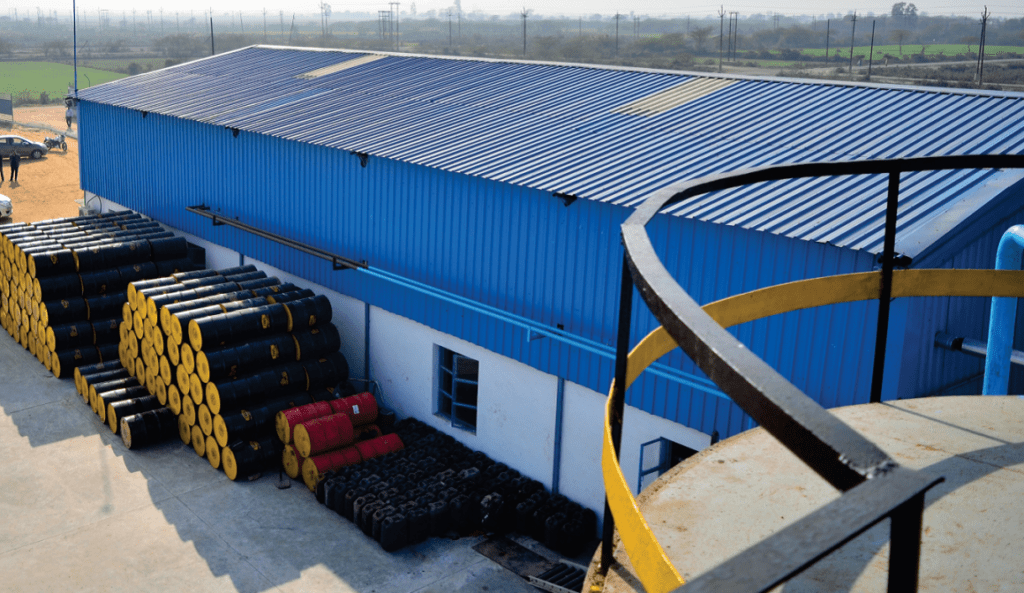

Kosi Factory

(near Mathura)

January 2017 saw the commissioning of IWL's fourth manufacturing facility at Mathura, Uttar Pradesh. It features completely micro-processor controlled machinery for the manufacture of bituminous emulsion. Storage capacities are significantly higher than IWL's other facilities. With this new plant, IWL now has a manufacturing location within 500 km of almost every location in India. We have brought ourselves closer to our customers, to serve them better.

Our new line

(Alamathy Factory)

To cater to an ever growing market, but with an emphasis on quality, IWL recently set up a new line for manufacturing APP and SBS modified bituminous membranes. The line is housed at IWL's Alamathy plant and was installed in a record time of 2 months from start to finish. The high speed line has an installed capacity of 30,000 sqm of membrane per working day. for the manufacture of Modified Bitumen membranes.The line is highly automated, requiring just 4 operators. The line is capable of producing a variety of membranes, with Mineral, Aluminium or plain finishes, and with a choice of reinforcements. The aesthetics and performance of the final product is par excellence. Now the pride of IWL, the line manufactures membrane to international specifications and the products from the new line have received praise from one and all.